Spotting a fake is easy — until it’s your brand on the line.

In today’s fast-paced digital marketplace, counterfeiters are smarter, faster, and more organized than ever. They replicate packaging, clone QR codes, and even build fake websites that mirror authentic ones.

Relying on a single layer of protection is no longer enough. What brands need today is a smarter, connected, and traceable defense system.

That’s exactly where Phygital Authentication steps in — a seamless blend of physical security and digital verification that ensures every product remains genuine, trackable, and trusted.

What Is Phygital Authentication?

The word “Phygital” combines physical + digital.

It’s the next evolution in brand protection and anti-counterfeiting technology.

Imagine combining:

- Physical features such as holograms, tamper-evident seals, or unique labels, with

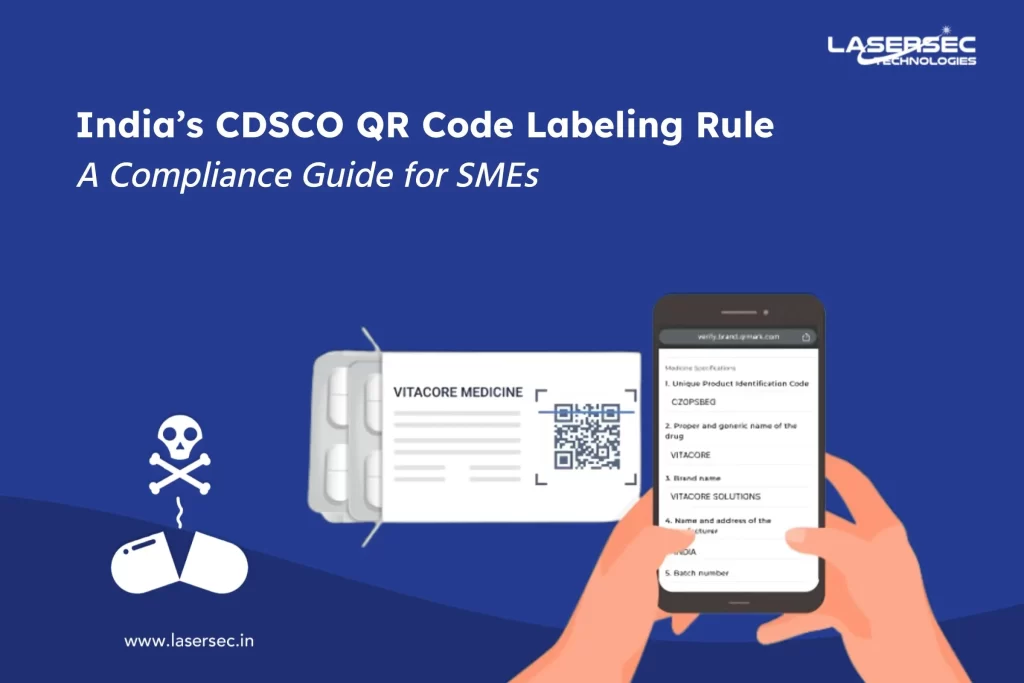

- Digital tools such as secure QR codes, NFC tags, or blockchain links.

Together, these create a two-factor authentication system for products:

- Physical layer: Provides instant, visible proof of authenticity.

- Digital layer: Enables real-time online verification, tracking, and analytics.

This powerful combination makes verification intuitive, transparent, and nearly impossible to replicate.

Why Every Industry Needs to Go Phygital

Counterfeiting is no longer limited to luxury or pharma — it’s now a multi-industry threat. From FMCG and automobile parts to electronics and apparel, fake products infiltrate every market, damaging brand reputation and consumer trust.

- A consumer could unknowingly buy a fake skincare product that looks identical to the real one.

- A patient could receive a counterfeit medicine, risking serious health consequences.

- A dealer might end up stocking duplicate machine parts, affecting equipment performance.

Phygital Authentication helps track products from factory to shelf, offering end-to-end supply chain visibility. It empowers brands to identify, trace, and stop counterfeit products — before they reach consumers.

The Power of Combining Physical and Digital Security

Phygital Authentication strengthens brand protection through dual assurance:

- Physical identifiers (holograms, foils, tamper seals) → provide instant visual confirmation.

- Digital identifiers (unique QR codes, serialized data, blockchain records) → enable live product authentication and data analytics.

Result: A powerful, tamper-resistant system that ensures authenticity, traceability, and accountability across the entire product lifecycle.

Each scan tells a story — one of trust, transparency, and technology working hand-in-hand.

Beyond Counterfeit Protection — Building Consumer Trust

Phygital Authentication isn’t only about protecting brands; it’s about creating genuine connections.

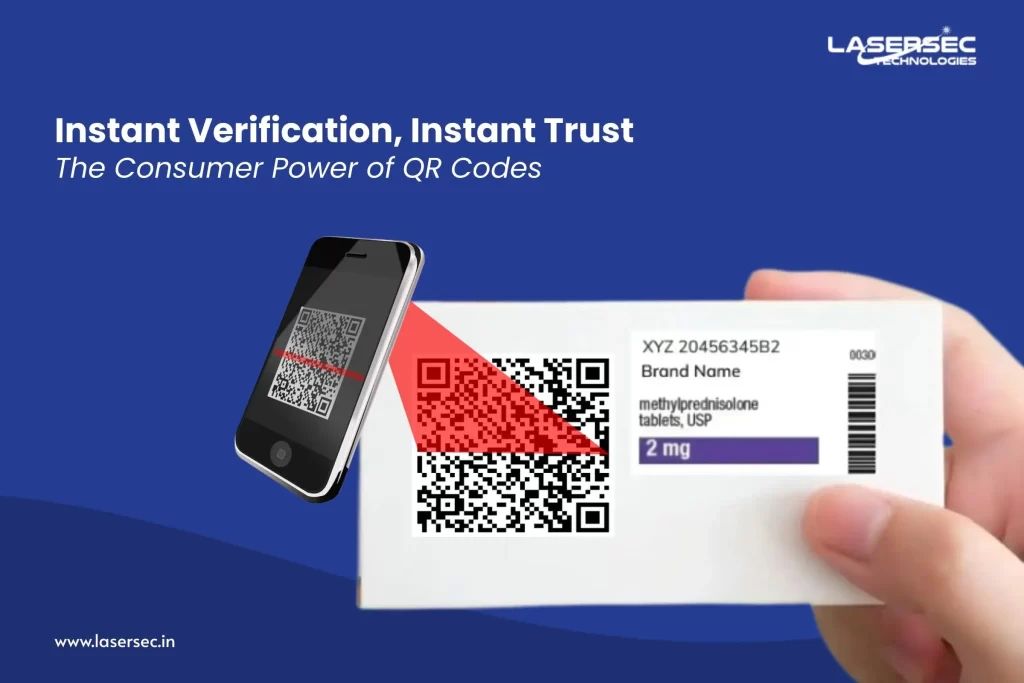

When customers scan a product and instantly verify its authenticity — or receive personalized information, rewards, or thank-you notes — it turns a simple purchase into an emotional experience. This sense of assurance and appreciation builds lasting loyalty and brand trust.

In an era of endless choices, trust isn’t optional — it’s your strongest advantage.

Future-Proofing Brand Protection

Counterfeiters are evolving — but so is technology.

Phygital Authentication ensures brands stay one step ahead with scalable, intelligent, and data-driven protection.

By merging physical security features with digital intelligence, brands unlock:

- Real-time product traceability

- Anti-counterfeiting analytics

- Consumer engagement opportunities

- Regulatory compliance support

This makes it not just a security solution — but a strategic investment in long-term brand integrity.

The future of anti-counterfeiting isn’t about choosing between physical or digital — it’s about merging both.

Phygital Authentication represents the next leap in brand protection, enabling businesses to:

- Secure every product

- Strengthen customer confidence

- Ensure full supply chain transparency

How Lasersec Technologies Powers Phygital Authentication

At Lasersec Technologies, we integrate cutting-edge physical and digital security to deliver true Phygital Authentication. Our portfolio includes holographic foils, tamper-evident seals, dynamic QR codes, and track-and-trace systems — all designed to create a connected, secure, and transparent product ecosystem. Each solution is customized to meet your industry’s compliance needs while strengthening brand integrity and consumer trust.

Partner with Us to Build a Phygital Future

Whether you’re in pharma, FMCG, apparel, electronics, or automotive, Lasersec Technologies helps your brand stay ahead of counterfeit threats. Connect with us for a consultation or demo to experience how our Phygital Authentication solutions can transform your brand protection strategy.