In today’s competitive marketplace, building and maintaining brand loyalty is a challenge. Consumers seek more than just quality products—they demand trust, transparency, and assurance. Tamper-evident labels offer a solution by ensuring security, authenticity, and peace of mind. Let’s explore how these technologies foster customer trust and encourage repeat purchases, ultimately driving brand loyalty.

Building Trust and Authenticity

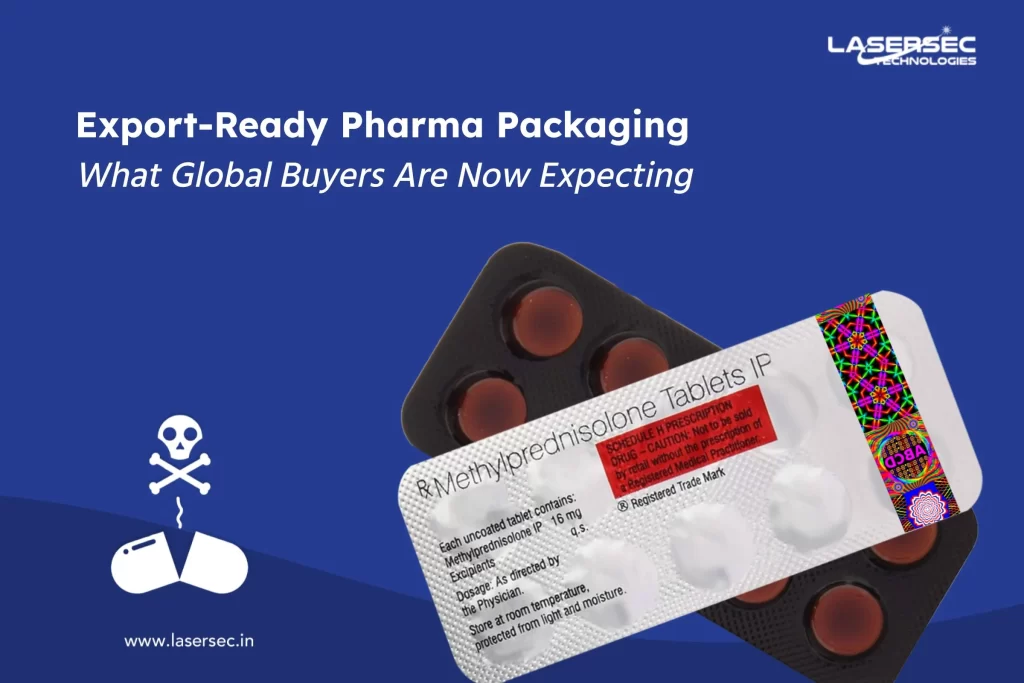

Tamper-evident labels provide clear evidence if a product has been altered. This feature is crucial for industries like pharmaceuticals, food, electronics, and luxury goods, ensuring customers receive products in their original, untampered state.

For consumers, knowing a brand prioritizes safety by investing in such technologies creates a solid foundation of trust. This commitment not only builds confidence in the product but strengthens the brand’s reputation, encouraging customer loyalty.

Counterfeit products undermine trust and brand reputation. Tamper-evident labels act as a shield against counterfeiting. Features like holograms, QR codes, and unique serial numbers allow customers to verify a product’s authenticity instantly. This transparency fosters confidence, reassuring customers that they are buying genuine, high-quality items.

Positive Customer Experiences and Repeat Purchases

Customer experience is key to driving repeat purchases. Tamper-evident labels enhance this experience by ensuring that products arrive intact, reinforcing a customer’s decision to purchase from that brand again.

Many tamper-evident labels incorporate interactive features like QR codes that provide product details, usage instructions, or even promotional offers. These elements add value beyond the product, engaging customers and nurturing a deeper connection with the brand.

Showcasing Brand Responsibility

Brands that prioritize tamper-evident technologies demonstrate their commitment to quality, safety, and customer satisfaction. This resonates with consumers, who are increasingly drawn to brands that show care and responsibility.

Additionally, tamper-evident labels help ensure compliance with industry regulations, particularly in pharmaceuticals and food. Meeting these standards not only ensures product integrity but also gives brands a competitive edge, further solidifying customer loyalty.

Innovation: The Key to Strengthening Loyalty

As consumer expectations evolve, brands must innovate to stay ahead. Tamper-evident technologies have advanced, offering features like smart labels that integrate with supply chain systems or loyalty programs. These innovations enhance security and open new ways to engage with customers.

For example, a smart tamper-evident label might notify customers when their product has been shipped or alert them if a package has been tampered with. Such innovations elevate the customer experience, making them feel valued and connected to the brand.

Tamper-evident labels are not just a security measure; they are a vital tool for building brand loyalty. By ensuring product integrity, combating counterfeiting, and creating positive customer experiences, these labels foster long-term relationships with consumers. As brands continue to embrace innovation and responsibility, tamper-evident technologies will remain a cornerstone in the pursuit of trust and customer loyalty.

Investing in tamper-evident solutions protects not just your products, but also the trust and loyalty your brand depends on. In a world where trust is currency, these labels are an invaluable asset.

Transform Your Brand’s Loyalty Strategy

Tamper-evident labels are more than just a protective measure—they are a critical component of an overarching strategy to enhance brand loyalty, build trust, and stay ahead of counterfeiting threats. At Lasersec Technologies, we specialize in advanced anti-counterfeit solutions, including tamper-evident technologies designed to meet your industry’s unique challenges.

Let us help you ensure your products’ integrity and build lasting relationships with your consumers. Ready to elevate your brand’s commitment to security and authenticity? Contact us at mktg@lasersec.in or call +91-9810213127 to learn more about how our tamper-evident solutions can benefit your business.