The healthcare industry faces an ever-growing challenge: the proliferation of counterfeit products. While much attention is given to counterfeit medications, the scope of this problem extends far beyond drugs. Medical devices, testing kits, hospital supplies, and even personal protective equipment (PPE) are also vulnerable to counterfeiting, posing significant risks to patient safety and regulatory compliance.

As counterfeiters become more sophisticated, it’s crucial to adopt comprehensive anti-counterfeiting strategies that encompass the full spectrum of healthcare products. Medical devices, from life-saving machines to simple diagnostic tools, play an essential role in healthcare delivery.

However, the rise in counterfeit devices has led to devastating consequences, including malfunctioning equipment, inaccurate diagnoses, and even loss of life. Counterfeit medical devices are often difficult to distinguish from genuine ones, making it even more challenging to detect their presence within supply chains. Whether it’s a faulty pacemaker, a defective blood pressure cuff, or a substandard ventilator, these products undermine the trust that healthcare professionals and patients place in medical technology.

Beyond drugs and devices, hospital supplies such as syringes, needles, and surgical instruments are at risk. Counterfeit versions of these critical items are often subpar in quality, which can result in dangerous complications during procedures or inadequate treatment of patients. With a global shortage of medical supplies exacerbated by the pandemic, counterfeit goods have infiltrated even the most trusted supply chains.

Counterfeit Solutions for Healthcare

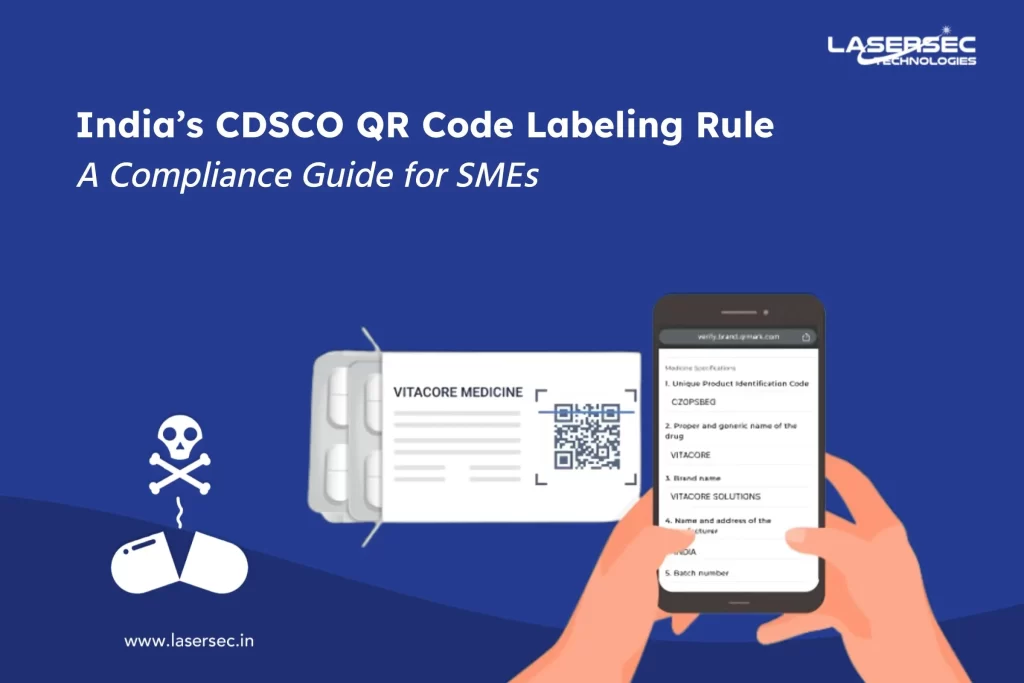

The solution to the widespread issue of counterfeit healthcare products lies in a multi-faceted approach. Anti-counterfeiting technologies such as holographic patterns, tamper-evident packaging, and QR code authentication can be integrated into medical products to ensure their authenticity. These technologies help create a unique identity for each product, allowing consumers and healthcare professionals to verify the product’s origin and integrity.

Track-and-trace systems have also become increasingly important in healthcare. By integrating blockchain-enabled verification into supply chains, the movement of products from manufacturers to consumers can be monitored in real-time. This not only helps identify counterfeit goods but also ensures compliance with regulatory standards.

As the fight against counterfeit products intensifies, packaging technology plays a pivotal role in safeguarding the integrity of medical supplies. Eco-friendly foils and biodegradable packaging solutions provide an added layer of protection while aligning with the growing emphasis on sustainable business practices. These solutions not only offer security features like holograms and tamper-evident seals but also address environmental concerns, helping the healthcare industry reduce its carbon footprint without compromising on safety.

At Lasersec Technologies, we are dedicated to offering cutting-edge, sustainable packaging solutions that protect your brand and ensure product authenticity. Our biodegradable, eco-conscious holographic foils are crafted to meet the evolving needs of the healthcare industry while upholding the highest security standards.

We invite you to explore our range of innovative anti-counterfeiting solutions and discover how our eco-friendly foils can strengthen your packaging strategies. Reach out to us today for more information or to request a personalized demo. Together, we can safeguard the integrity of healthcare products and contribute to a safer, more sustainable future.

For more details, contact us at mktg@lasersec.in or call +91-9810213127.