Counterfeit products are an escalating issue worldwide, but their impact is especially devastating in emerging markets, where regulatory frameworks and enforcement capabilities are often still developing. From pharmaceuticals and FMCG to electronics and apparel, counterfeit goods pose significant risks, including endangering lives, undermining brand reputation, and slowing economic progress. This blog delves into why anti-counterfeiting solutions are essential for these markets and how they can address critical challenges to create a safer and more robust industrial ecosystem.

The Scale of Counterfeiting in Emerging Markets

Emerging markets such as India, Southeast Asia, Africa, and parts of South America are highly vulnerable to counterfeiting. According to the Organisation for Economic Co-operation and Development (OECD), counterfeit goods account for 3.3% of global trade, with a significant concentration in emerging regions.

Key drivers behind this issue include:

- Weak Enforcement of Regulations: Many emerging markets lack the resources or updated policies to combat counterfeiting effectively.

- Affordable Counterfeits Flooding the Market: A large population with limited purchasing power often chooses counterfeit goods over authentic ones, unknowingly risking their health and safety.

- Complex and Globalized Supply Chains: Counterfeiters exploit gaps in traceability and security during the manufacturing and distribution process.

Why Anti-Counterfeiting Solutions Are Indispensable

1. Ensuring Consumer Safety

Counterfeit products can cause irreversible harm, particularly in industries like pharmaceuticals. For instance, a study by the World Health Organization (WHO) found that 1 in 10 medical products in low- and middle-income countries is substandard or fake.

Example: A counterfeit malaria drug in Africa recently resulted in thousands of deaths due to ineffective treatment.

Implementing advanced track-and-trace systems, tamper-evident packaging, and holographic foils ensures that only safe, authentic products reach end users.

2. Preserving Brand Reputation

A brand is only as strong as the trust consumers place in it. Counterfeit products tarnish this trust and harm long-term customer loyalty. Anti-counterfeiting technologies like holographic labels, security QR codes, and blockchain systems safeguard brands by making counterfeiting nearly impossible.

Example: A leading electronics brand in India implemented QR code-based verification on its packaging, drastically reducing counterfeit complaints.

3. Boosting Economic Growth

Counterfeiting drains resources from legitimate businesses and reduces government tax revenues. The International Chamber of Commerce estimates that counterfeiting and piracy cost the global economy $4.2 trillion annually. By adopting anti-counterfeiting measures, businesses in emerging markets can thrive, creating jobs and boosting GDP.

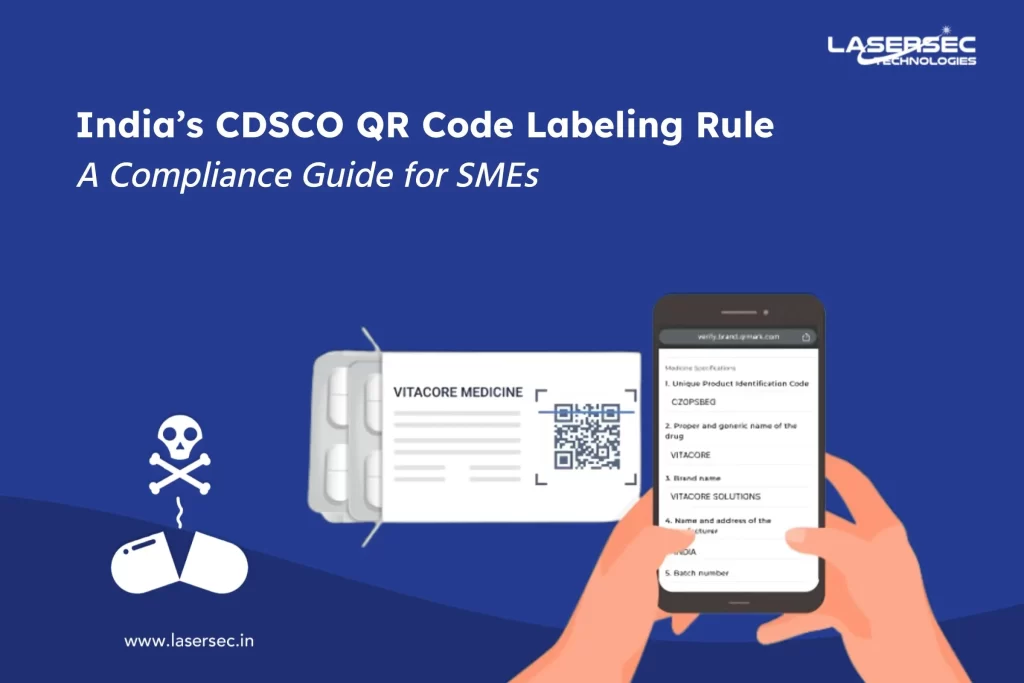

4. Facilitating Regulatory Compliance

Governments in emerging markets are increasingly introducing stringent regulations, especially in pharmaceuticals and FMCG.

Example:

India’s Drug Authentication & Verification Application (DAVA): Requires pharmaceutical exporters to serialize and track products through QR codes.

Brands that adopt serialization and track-and-trace systems stay ahead of regulatory demands, reducing compliance risks.

5. Enhancing Global Trade Credibility

Counterfeiting affects not just local markets but also the global perception of emerging market brands. By incorporating holographic technologies and other advanced solutions, these brands can build international credibility, opening doors to broader trade opportunities.

Tailored Anti-Counterfeiting Solutions for Emerging Markets

Holographic Technologies

Cost-effective and visually distinctive, holograms are a proven way to authenticate products. These can be used as labels, security strips, or integrated into packaging.

Track-and-Trace Systems

Digital traceability ensures complete transparency across the supply chain, identifying counterfeit interference early.

QR Code Authentication

Easily scanned by consumers, QR codes empower buyers to verify authenticity directly, increasing trust in the product.

Tamper-Evident Packaging

Packaging that visibly reveals interference deters counterfeiters while reassuring consumers.

Blockchain Solutions

Immutable and transparent, blockchain technology provides end-to-end product verification, making it ideal for industries like luxury goods and pharmaceuticals.

A Brighter Future for Emerging Markets

For emerging markets to unlock their full potential, tackling counterfeiting is essential. With the right combination of anti-counterfeiting technologies and strategic implementation, industries can protect consumer safety, preserve brand trust, and fuel economic growth.

Let’s work together to secure your brand and supply chain from counterfeit threats. Contact us today for a demo of our advanced anti-counterfeiting solutions!

About Lasersec Technologies

We are a leading manufacturer of holographic solutions designed to combat counterfeiting. Our dedicated R&D team continuously seeks innovative solutions, ensuring that all our offerings are original and free from external interference. With successful business alliances in Bangladesh, South Africa, Malaysia, Sri Lanka, Nepal, the United Kingdom, and across Europe, we are committed to enhancing product security worldwide.

You can reach us via email at mktg@lasersec.in or by phone at +91-9810213127.