A consumer picks up a bottle of cooking oil, a pack of biscuits, or a personal care product from a store shelf. Before checking the price or brand, there is a quiet, instinctive question:

Has this product been opened before?

In the FMCG sector, where products are consumed daily and often immediately, consumer trust is built in seconds. Tamper-proof seals play a decisive role in this moment. They provide visible proof of product safety, protect hygiene, and reassure consumers that the brand has taken responsibility seriously.

For FMCG brand owners, packaging professionals, and quality teams, tamper-evident packaging is no longer optional. It is a foundational element of consumer confidence and brand protection.

Why Tamper Evidence Is Critical in the FMCG Industry

Fast-moving consumer goods directly affect health, hygiene, and everyday well-being. Even a small doubt about product integrity can lead to immediate rejection.

Without effective tamper-proof packaging, brands face risks such as:

- Loss of consumer trust at the point of purchase

- Product rejection at first use

- Brand damage amplified through social media and word of mouth

- Regulatory and retailer compliance challenges

Unlike durable goods, FMCG products allow no margin for uncertainty. A broken seal, loose cap, or unclear opening mechanism can raise concerns about contamination, adulteration, or prior use.

Tamper-evident seals eliminate this uncertainty by providing clear, irreversible evidence of first opening.

What Are Tamper-Proof Seals and How Do They Work?

Tamper-proof seals are packaging features designed to make any unauthorized opening immediately visible and impossible to reverse without detection.

Common tamper-evident packaging mechanisms used in FMCG include:

- Breakable caps and tear bands

- Induction seals for bottles and containers

- Tamper-evident labels and void seals

- Peel-off seals with irreversible damage indicators

Once opened, these mechanisms cannot return to their original state. This simple principle—open once, show forever—is what makes tamper-proof seals so effective for consumer safety and trust.

How Tamper-Proof Seals Reassure Consumers at the Point of Purchase

Consumers may not understand packaging technology, but they clearly understand visual safety cues.

Tamper-evident packaging reassures consumers by offering:

- Immediate visual confirmation that the product is untouched

- Clear break-to-open indicators signaling first use

- A consistent safety experience across batches and retail locations

This reassurance is especially important in high-sensitivity FMCG categories such as:

- Food and beverages

- Dairy and edible oils

- Personal care and cosmetics

- Home hygiene and cleaning products

- Baby care and wellness items

In these segments, visible packaging safety directly influences buying decisions.

Maintaining Product Safety and Hygiene Across the Supply Chain

From manufacturing facilities to retail shelves, FMCG products pass through multiple touchpoints. Tamper-proof seals act as a silent guardian throughout this journey.

They help brands:

- Detect unauthorized access during transportation and storage

- Prevent product substitution, refilling, or partial usage

- Reduce contamination and mishandling risks

- Maintain hygiene until final consumption

For quality assurance and compliance teams, tamper-evident packaging provides a built-in control mechanism—one that complements audits, inspections, and process controls.

Protecting Brand Reputation in a Competitive FMCG Market

Brand reputation in FMCG is fragile and hard-earned. A single safety incident—real or perceived—can undo years of trust.

Tamper-proof seals support brand protection by:

- Demonstrating accountability and transparency

- Reducing the risk of counterfeit or refilled products entering the market

- Supporting regulatory and retailer packaging requirements

- Reinforcing a brand’s commitment to consumer well-being

When consumers repeatedly experience sealed, safe, and reliable packaging, trust becomes habitual—and brand loyalty follows.

Tamper Evidence as a Brand Trust Signal

Modern consumers expect brands to anticipate risks, not react to them. Tamper-proof seals send a subtle but powerful message:

This brand has prioritised your safety before you even asked.

For packaging and brand protection leaders, tamper evidence goes beyond compliance. It becomes a visible signal of responsibility, quality, and care—values that increasingly influence consumer choice.

Building Consumer Confidence Beyond the First Use

Consumer confidence does not end at the point of purchase. It extends to the moment of opening, daily usage, and repeat buying decisions.

A well-designed tamper-proof seal ensures that:

- The first interaction reinforces trust

- Product safety expectations are consistently met

- Consumers feel confident repurchasing the same brand

In a category defined by frequent replacement and intense competition, this consistency is what separates trusted FMCG brands from forgettable ones.

Final Thoughts: Small Seal, Lasting Impact on FMCG Brands

Tamper-proof seals may appear simple, but their impact on FMCG packaging security is significant. They safeguard product integrity, protect hygiene, support compliance, and—most importantly—build consumer confidence where it matters most.

For FMCG brands focused on long-term trust, safety, and sustainable growth, investing in effective tamper-evident packaging is not merely a regulatory step. It is a strategic decision that strengthens the relationship between the brand and the consumer—one seal at a time.

How Lasersec Technologies Supports Smarter Packaging Security

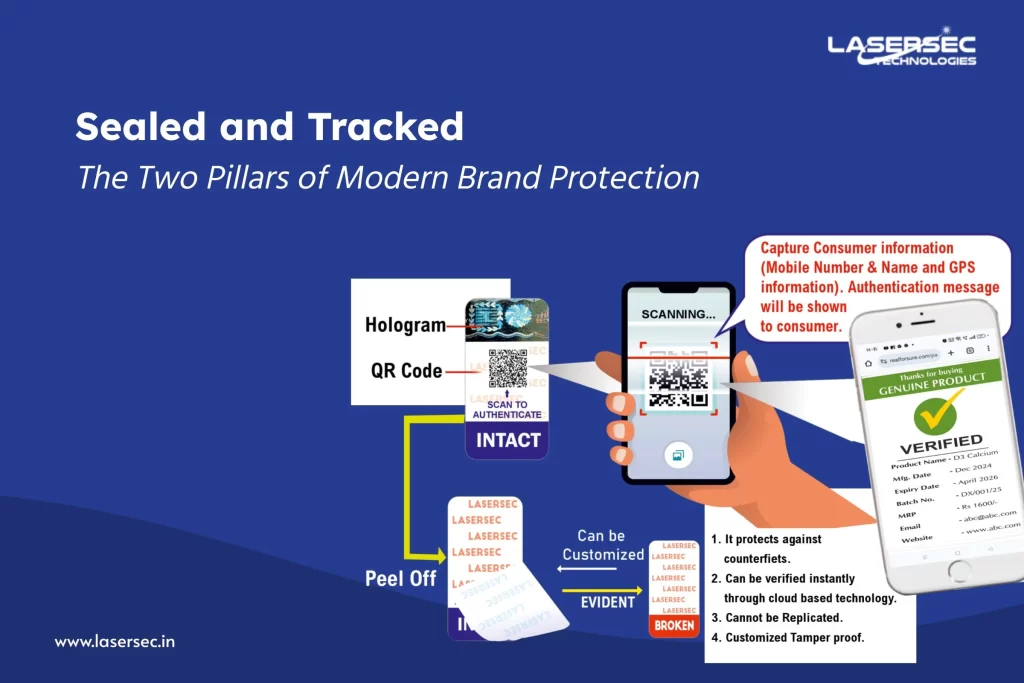

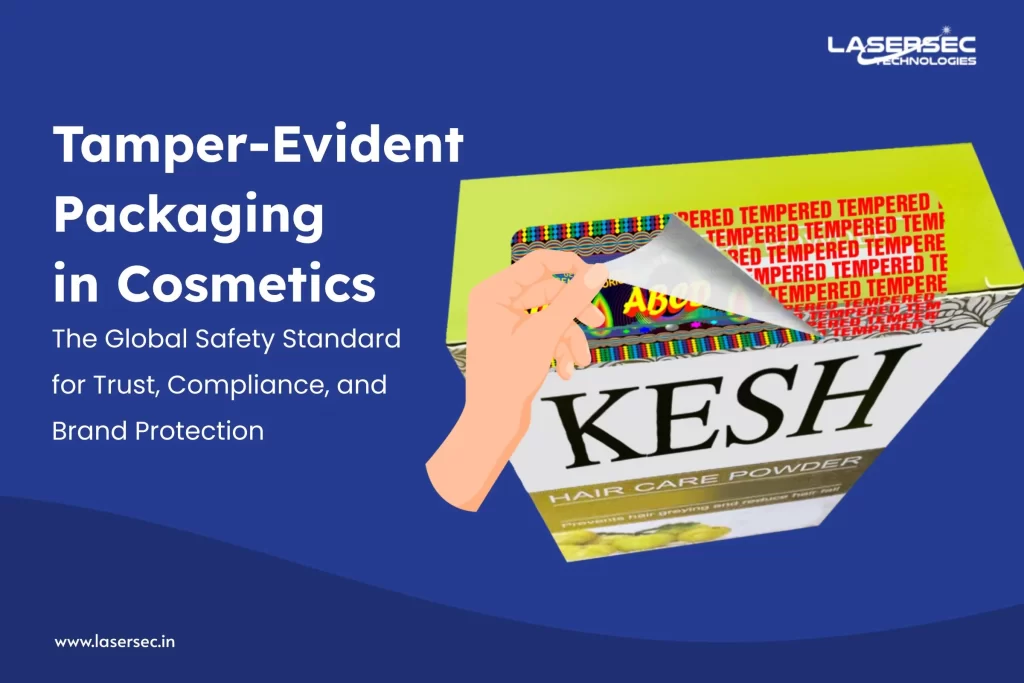

At Lasersec Technologies, we help FMCG brands strengthen consumer trust through tamper-evident andphygital packaging solutions that combine visible security with digital authentication. Our solutions integrate security holograms, tamper-proof labels, QR-based verification, and track-and-trace systems to protect products across the supply chain. Each deployment is designed to meet compliance requirements while reinforcing brand integrity and packaging reliability.

Partner with Lasersec Technologies for Trusted FMCG Packaging

From food and personal care to hygiene and wellness products, Lasersec Technologies works with FMCG brands to build packaging systems that consumers can trust at first glance. Connect with our team to explore how tamper-evident and phygital packaging can strengthen your brand protection strategy.