A shopper picks up your product from a neighborhood store. They scan the pack, expecting a reward — loyalty points, cashback, or a small surprise.

But what if the same reward has already been claimed using a counterfeit version of your product?

For FMCG brands operating in high-volume, price-sensitive markets, this is no longer a rare edge case. It is a growing reality that is quietly forcing loyalty programs to evolve.

Today, phygital loyalty programs are emerging as a critical solution — ensuring that consumer rewards are unlocked only through genuine, authenticated FMCG products.

Loyalty in FMCG Is Built on Trust, Not Just Rewards

In fast-moving consumer goods, loyalty is driven by habit, availability, and confidence. Consumers repeatedly choose brands they trust — brands that feel fair, reliable, and transparent.

However, when loyalty programs can be exploited:

- Genuine consumers feel cheated

- Counterfeit products benefit from real promotions

- Marketing spends increase without proportional growth

Over time, promotional excitement turns into doubt. And once trust erodes, loyalty weakens.

This is why FMCG brand loyalty programs must prioritize fairness and authenticity, not just engagement metrics.

Why Traditional Loyalty Programs Fail in FMCG Environments

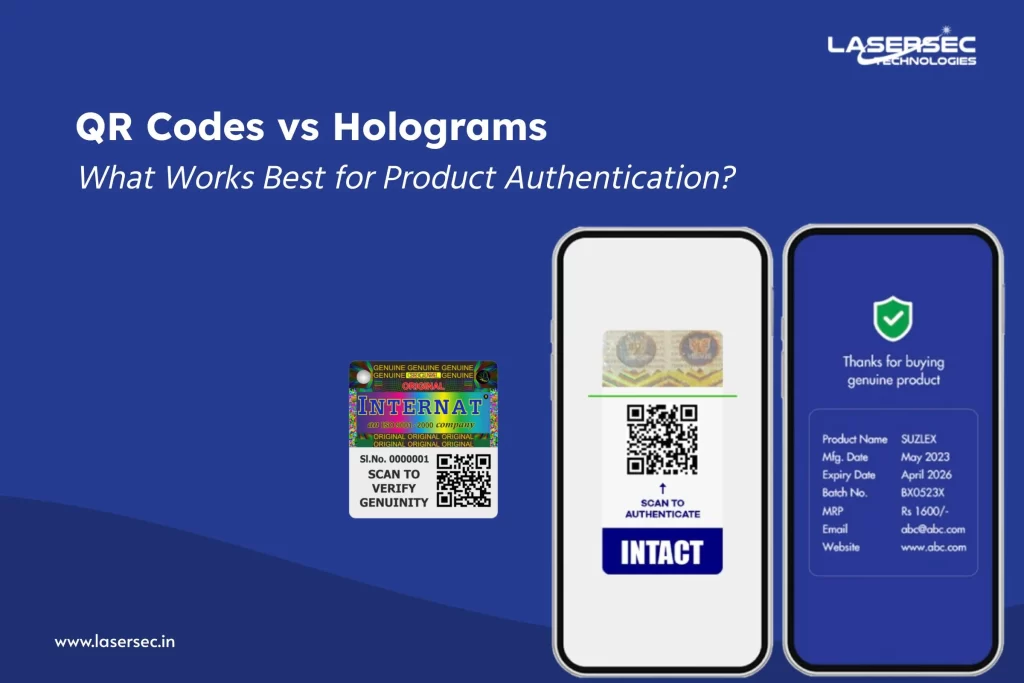

Most conventional loyalty programs rely on printed QR codes, alphanumeric codes, or digital coupons. While these methods increase participation, they introduce serious vulnerabilities.

Common issues include:

- Codes being copied, shared, or resold

- Multiple redemptions from a single code

- Rewards claimed without a genuine product purchase

For FMCG brands running nationwide or multi-country campaigns, this results in:

- Misallocated rewards and promotional leakage

- Inaccurate campaign performance data

- Increased scrutiny from finance and audit teams

The challenge is not loyalty itself — it is verifying who truly deserves the reward.

What Is a Phygital Loyalty Program?

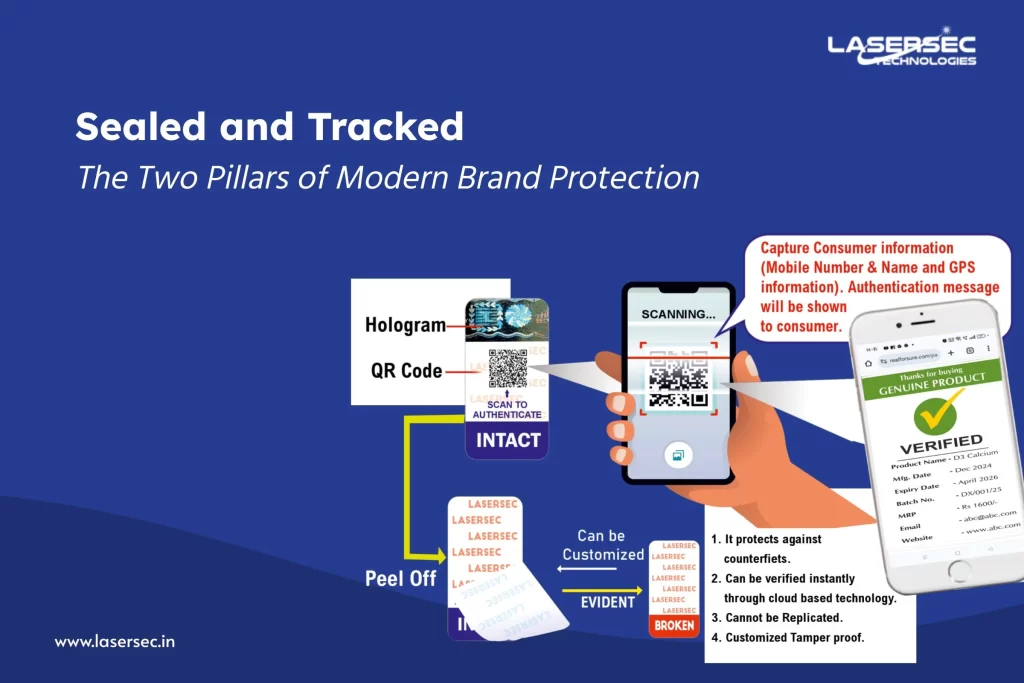

A phygital loyalty program connects physical product authentication with digital consumer engagement.

Unlike traditional systems, phygital loyalty ensures that:

- The physical product is authenticated first

- Authenticity is verified through a secure scan

- Rewards are unlocked only after verification

By linking product authentication and loyalty rewards, FMCG brands ensure that incentives flow only from genuine products.

This approach builds directly on track and trace authentication systems and transforms loyalty from a volume-driven tactic into a trust-driven strategy.

A Better Loyalty Experience for FMCG Consumers

From the consumer’s perspective, phygital loyalty feels simple yet reassuring.

A single scan provides:

- Instant confirmation that the product is genuine

- Access to loyalty rewards or offers

- Brand-backed product information and guidance

That moment of reassurance matters.

In everyday FMCG categories — food, beverages, personal care, home essentials — this subtle confirmation strengthens confidence and encourages repeat purchases.

Authenticity becomes part of the consumer experience, not an afterthought.

How Phygital Loyalty Helps FMCG Brand and Marketing Teams

For internal stakeholders, phygital loyalty programs deliver measurable value.

They help FMCG brands:

- Protect promotional budgets from misuse

- Ensure rewards reach genuine buyers

- Improve campaign ROI measurement

- Capture clean, reliable engagement data

When loyalty rewards are tied to secure product authentication technologies, campaigns become auditable, defensible, and scalable.

Loyalty stops being a risk — and starts becoming a strategic asset.

Counterfeiting Is a Mass-Market FMCG Problem

Counterfeiting is no longer limited to premium or luxury categories. In FMCG supply chains, counterfeit products move quickly and blend easily with genuine stock.

When promotions are attached to unauthenticated products, counterfeit circulation accelerates.

Phygital loyalty programs help FMCG brands:

- Discourage counterfeit participation in campaigns

- Reduce misuse of brand-funded incentives

- Reinforce trust at the point of purchase

This is particularly critical in emerging markets across Asia, Africa, the Middle East, and Latin America, where volume, price sensitivity, and complex distribution networks increase risk.

How Lasersec Technologies Enables Phygital Loyalty

At Lasersec Technologies, we help FMCG brands integrate product authentication with loyalty programs through scalable phygital solutions.

Our approach combines:

- Physical security features embedded into packaging

- Secure scan-based authentication technologies

- Digital systems that integrate seamlessly with loyalty platforms

These solutions are built using advanced anti-counterfeit packaging technologies and digital validation layers.

The result is a loyalty ecosystem where rewards are unlocked only through genuine FMCG products — protecting consumers, campaigns, and brand equity.

How Phygital Loyalty Helps FMCG Brand and Marketing Teams

For internal stakeholders, phygital loyalty programs deliver measurable value.

They help FMCG brands:

- Protect promotional budgets from misuse

- Ensure rewards reach genuine buyers

- Improve campaign ROI measurement

- Capture clean, reliable engagement data

When loyalty rewards are tied to secure product authentication, campaigns become auditable, defensible, and scalable.

Loyalty stops being a risk — and starts becoming a strategic asset.

How Phygital Authentication Powers Secure Loyalty Programs

Phygital loyalty programs only work when the product itself is verified as genuine. Without secure authentication, rewards can still be misused through counterfeit products.

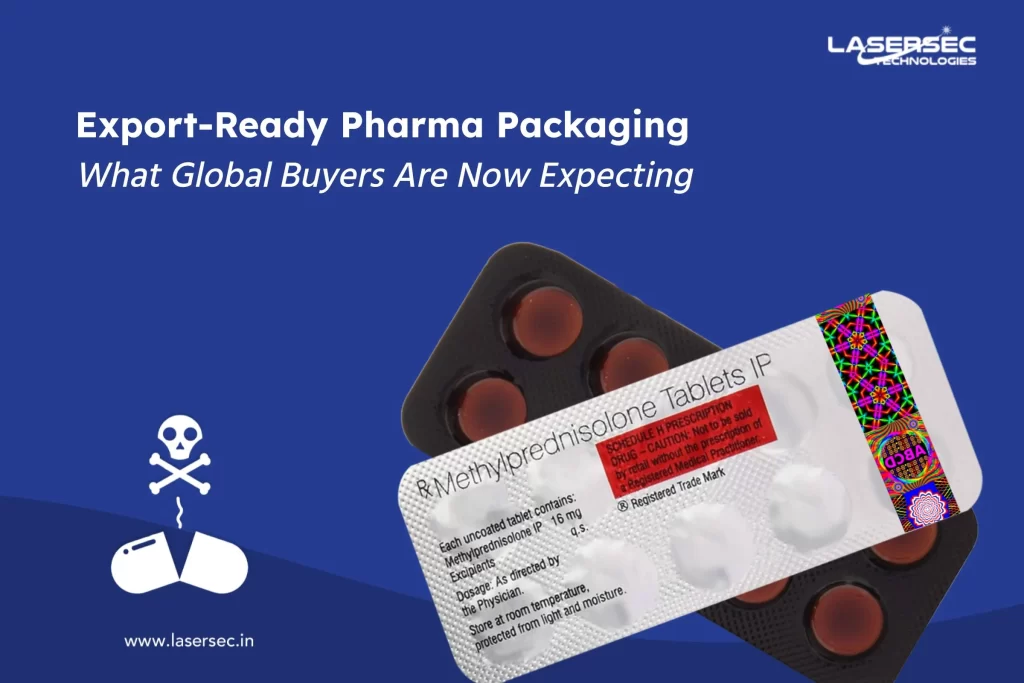

At Lasersec Technologies, phygital authentication is built by integrating physical and digital security into a single, connected ecosystem. This includes holographic foils, tamper-evident seals, dynamic QR codes, and track-and-trace systems embedded directly into FMCG packaging.

Each consumer scan first confirms product authenticity and packaging integrity. Only after successful verification are loyalty rewards unlocked. This prevents duplicate claims, code copying, and reward misuse linked to counterfeit products.

By connecting authentication with loyalty systems, FMCG brands create a transparent, secure, and controlled reward environment — one where incentives are triggered only by genuine products.

Counterfeiting Is a Mass-Market FMCG Problem

Counterfeiting is no longer limited to premium or luxury categories. In FMCG supply chains, counterfeit products move quickly and blend easily with genuine stock.

When promotions are attached to unauthenticated products, counterfeit circulation accelerates.

Phygital loyalty programs help FMCG brands:

- Discourage counterfeit participation in campaigns

- Reduce misuse of brand-funded incentives

- Reinforce trust at the point of purchase

This is particularly critical in emerging markets across Asia, Africa, the Middle East, and Latin America, where high volumes and complex distribution networks increase exposure.

Why Phygital Loyalty Is the Future of FMCG Engagement

As counterfeit risks rise and consumers demand transparency, loyalty programs must evolve.

Phygital loyalty programs enable FMCG brands to:

- Build long-term consumer trust

- Reduce promotional fraud

- Strengthen brand credibility across markets

- Create fair, data-driven engagement systems

Loyalty is not built by giving more rewards.

It is built by ensuring that the right rewards reach the right consumers — through genuine products.

When authenticity comes first, trust follows naturally. And when trust is sustained, loyalty lasts — across products, campaigns, and years.

Partner with Us to Build a Phygital Future

Whether you’re in pharma, FMCG, apparel, electronics, or automotive, Lasersec Technologies helps your brand stay ahead of counterfeit threats. Connect with us for a consultation or demo to experience how our Phygital Authentication solutions can transform your brand protection strategy.

Email: mktg@lasersec.in | Phone: +91-9810213127