Counterfeit products are a growing problem that can cause significant damage to businesses, consumers, and the economy. According to the Organization for Economic Co-operation and Development (OECD), the global trade in counterfeit goods is estimated to be worth over $500 billion annually.

Several industries, including luxury goods, technology, pharmaceuticals, and food products, produce counterfeit goods. In addition to seriously endangering the health and safety of people, counterfeit goods also hurt economies and legitimate enterprises by inhibiting innovation, growth, and investment. The usage of smart packaging is one of the most promising remedies for the issue of counterfeit goods.

Smart packaging is a potential solution to combat counterfeiting. Smart packaging incorporates technology into product packaging, providing additional features beyond the traditional functions of protection and containment. These features can include tamper-evident seals, authentication labels, and anti-counterfeiting technologies like QR codes, RFID tags, and holograms.

By incorporating these technologies into their packaging, businesses can prevent counterfeit products from entering the supply chain, protect consumer safety, and safeguard their brand reputation.

Smart packaging is an innovative solution that has the potential to revolutionize the way we think about packaging and its role in ensuring the safety and authenticity of the products we use every day. It offers a way to prevent counterfeiting and protect both consumers and businesses. Unlike traditional packaging, smart packaging can provide real-time information to consumers. The benefits of smart packaging are numerous and provide significant advantages for businesses.

Some of the most significant advantages include:

- Increased safety and security

- Better traceability

- Improved regulatory compliance

- Enhanced consumer engagement

- Supply chain optimization

Let’s talk about smart packaging we offer that can help prevent your products from being counterfeited.

Tamper-evident Holograms

Tamper-evident holograms are an essential feature of smart packaging. These holograms provide visual evidence that the product has been tampered with, which can deter counterfeiters from attempting to replace or alter the product. Tamper-evident holograms can include adhesive seals, shrink bands, and tear tapes, among others. These holograms are designed to break if the packaging is opened or tampered with, making it easy for consumers and retailers to spot any signs of interference. Read more

Anti-counterfeit Labels

Anti-counterfeit labels are another effective feature of smart packaging. These labels use advanced security features such as holograms, watermarks, or RFID tags to authenticate the product’s origin and contents. Anti-counterfeit labels can be scanned with a smartphone or other device, enabling consumers and retailers to verify the product’s authenticity and ensure that it has not been tampered with. Read more

QR codes

QR codes are increasingly used in smart packaging to provide additional information to consumers and retailers, including product details, manufacturer information, and expiration dates. QR codes can also be used as an anti-counterfeiting measure by encoding unique information into the code, which can be verified by the manufacturer or other authorized parties. Read More

Void and Tamper Proof Labels

Void and Tamper Proof Labels provide extra layer of protection to the products and it’s packaging. At the same time guarantee the authenticity of products and protects the integrity of the product throughout its supply chain. VOID Labels is one of the most used and liked label by various industries and their distributors. They are extremely customizable, protects from counterfeiting and is tamper proof because of it’s secure double printing seal. We offers security adhesives with an inviolability system. And can be customised adhesives which can have the logo of your company, the serial number of the product, or pre-set perforated lines. Read more

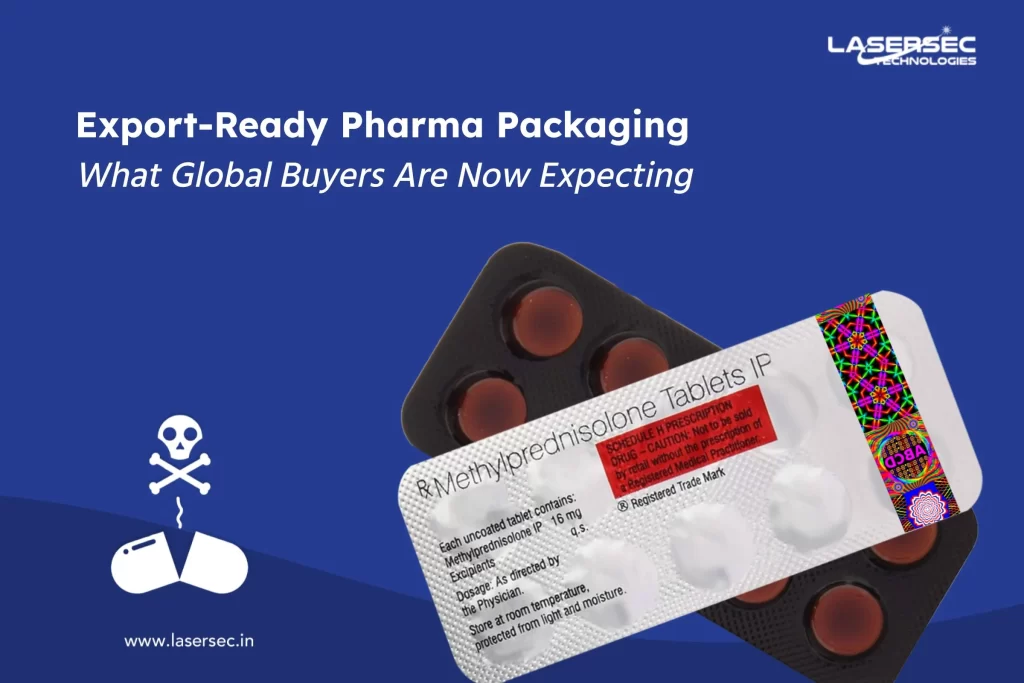

Blister Foil with Security Printing

The blister foil with security printing is a new way to sell products. It is a type of packaging that helps to prevent counterfeiting and also provides a way to track the product’s authenticity. This is safe and user friendly and ideal for all types of pharmaceutical wraps such as tablets and capsules. This packaging is more popular in the market because of its benefits. Read more

As the global economy continues to evolve, businesses must stay ahead of the curve by embracing new technologies and meeting the evolving needs of consumers. Smart packaging represents a powerful tool for achieving these goals and staying competitive in today’s rapidly changing marketplace. By investing in smart packaging and leveraging its many benefits, businesses can unlock new opportunities for growth, reduce costs, and build stronger relationships with customers.

If you’re a manufacturer or business and looking for smart packaging for your products, look no further than us. We have the knowledge, experience, and expertise to help you to find the best solution that works for your business.

Reach out to us to discuss and ur team will provide you with tailored solutions and support to make the process as smooth as possible. We also One Stop Solution to fight against counterfeit and create a more secure environment for your business. With less counterfeiting, you can maintain sales and increase customer trust.

Shield your business with our advanced technology solutions

About Lasersec Technologies

We are one of the leading holographic solutions manufacturing company, that are used as an anti-counterfeiting device. Our R&D team from the production area is constantly dedicated to finding innovative solutions against counterfeits. Thus, we proudly emphasize on the fact that all our solutions are original ones without any interference from any other outside companies. We have successful business alliances located in Bangladesh, South Africa, Malaysia, Sri Lanka, Nepal, United Kingdom, and countries of Europe.

You can reach us via email at mktg@lasersec.in or by phone at +91-9810213127.