In an industry where patient safety and trust are non-negotiable, pharmaceutical companies face increasing pressure to protect their products from the growing threat of counterfeiting. Fake drugs not only undermine consumer confidence but can also lead to dangerous health consequences. As a result, secure pharmaceutical packaging has never been more critical.

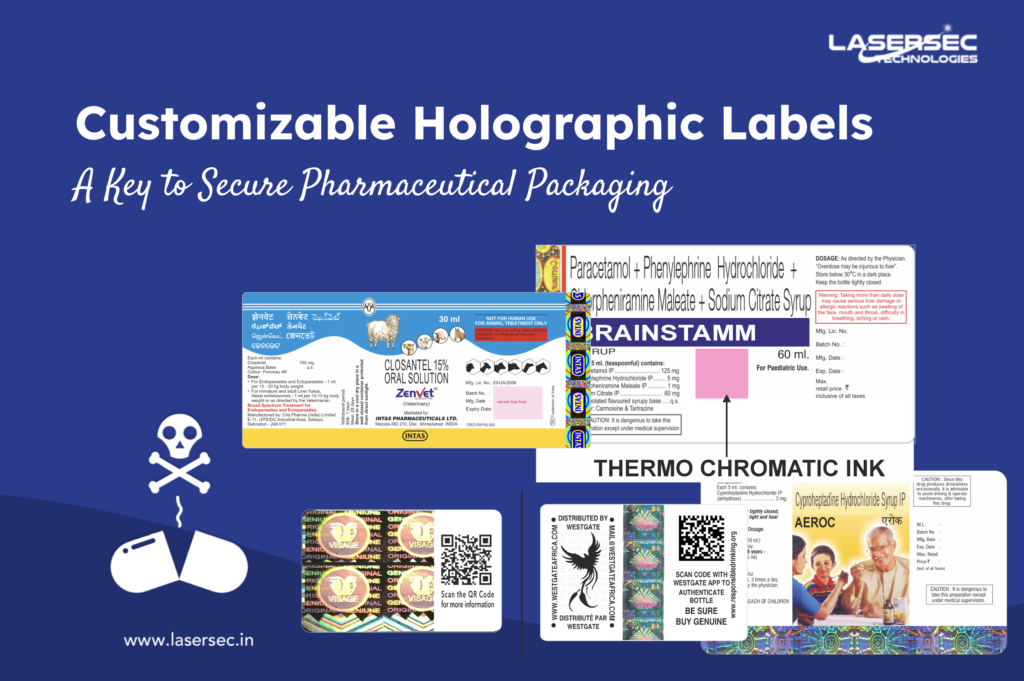

One of the most effective solutions to this challenge is the use of customizable holographic labels. These labels are not just security measures—they are advanced tools that combine technology, aesthetics, and innovation to safeguard products and brand reputation.

By integrating holography with features like QR codes, tamper-evident designs, and thermochromatic ink, these labels offer a robust defense against counterfeiting while ensuring that the packaging itself communicates quality and authenticity.

Let’s explore some of the most impactful holographic labels available for the pharmaceutical sector and how they play a crucial role in protecting both products and consumers.

1. Anti-counterfeit Label with QR Code:

This label merges holographic security with the digital authentication power of QR codes, creating a dual-layer protection system. The QR code allows consumers to quickly verify the authenticity of the product, while the holographic elements deter counterfeiting, making it a perfect choice for securing high-value pharmaceuticals.

2. Destructive Label:

Designed with a self-destruct mechanism, this label is a strong deterrent against tampering. Once applied, any attempt to remove the label results in its destruction, ensuring that counterfeiters cannot reuse it on fake products.

3. Holographic Cut Label:

These labels are designed with intricate holographic patterns and precision cutting, providing not only enhanced security but also a premium look. Ideal for pharmaceutical brands that want to stand out while protecting their products from counterfeiters.

4. Holographic Labels With Thermochromic Ink:

Incorporating thermochromatic ink, these labels change color with temperaturefluctuations. This feature adds another layer of security, making it easy to detect if the product has been exposed to inappropriate temperatures or tampered with during transport.

5. Holographic Pharma Label:

Specifically crafted for the pharmaceutical industry, this label includes advanced features like microtext and nano-imprinting, which are nearly impossible to replicate. This makes it an essential tool for safeguarding products from counterfeiting and ensuring product integrity.

6. Holographic QR Code Label:

Similar to the anti-counterfeit label, this option combines a QR code with holographic security, providing an easy and secure way for consumers to authenticate the product. This label is especially useful in track-and-trace systems, ensuring the product’s journey from manufacturing to the pharmacy is secure.

7. Holographic Self Adhesive Label:

These versatile labels are designed for easy application and strong adhesion, making them a practical solution for a wide range of pharmaceutical packaging needs. The holographic features not only enhance security but also add a layer of visual appeal that reinforces the brand’s commitment to quality.

8. Holographic Shrink Label:

Offering full coverage, this label wraps around products with complex shapes, ensuring that the holographic design remains intact and visible. This type of label provides continuous protection and branding from every angle.

9. Tamper Evident Label:

These labels are designed to leave a clear indication if tampered with, ensuring that any attempt to interfere with the product is immediately noticeable. This feature is crucial for maintaining consumer trust and ensuring that the product reaches the patient in its original, unaltered state.

10. Void & Tamper Proof Label:

This label leaves behind a “void” message if removed, signaling that the packaging has been compromised. This feature is particularly important for protecting high-value or sensitive pharmaceuticals, ensuring that consumers only receive genuine, untouched products.

As the pharmaceutical industry continues to combat the challenges of counterfeiting and product tampering, customizable holographic labels have emerged as a vital solution. These labels not only provide advanced security features that protect the product, but they also enhance the brand’s image, communicating a commitment to quality and safety.

By adopting these innovative labels, pharmaceutical companies can secure their products, protect their reputation, and most importantly, ensure the safety of their consumers.

Ready to Protect Your Brand?

Request a Demo to discover how our customizable holographic labels can elevate your pharmaceutical packaging and protect your brand in today’s competitive market!

Together, let’s combat counterfeiting and uphold the highest standards of quality and integrity in the automotive industry.

If you’re a manufacturer or business and looking for smart packaging for your products, look no further than us. We have the knowledge, experience, and expertise to help you to find the best solution that works for your business.

Reach out to us to discuss and our team will provide you with tailored solutions and support to make the process as smooth as possible. We also One Stop Solution to fight against counterfeit and create a more secure environment for your business. With less counterfeiting, you can maintain sales and increase customer trust.

Stay proactive, stay vigilant, and invest in the right anti-counterfeit solutions to ensure a counterfeit-free future.

About Lasersec Technologies

We are one of the leading holographic solutions manufacturing company, that are used as an anti-counterfeiting device. Our R&D team from the production area is constantly dedicated to finding innovative solutions against counterfeits. Thus, we proudly emphasize on the fact that all our solutions are original ones without any interference from any other outside companies. We have successful business alliances located in Bangladesh, South Africa, Malaysia, Sri Lanka, Nepal, United Kingdom, and countries of Europe.

You can reach us via email at mktg@lasersec.in or by phone at +91-9810213127.