In the fast-paced world of pharmaceuticals, packaging isn’t just about containment; it’s an artful blend of science, security, and branding. The journey from an idea to market-ready packaging is marked by continuous innovation, ensuring both safety and brand identity are preserved. Let’s dive into the exciting realm of pharmaceutical packaging design and discover how it aligns with today’s branding and security needs.

The Power of First Impressions

In an industry where trust is paramount, your product’s packaging is often the first interaction consumers have with your brand. Innovative packaging design capitalizes on this opportunity by creating a memorable first impression. From sleek and modern to eco-friendly and sustainable, the options are diverse, allowing pharmaceutical companies to communicate their values through design.

Sustainability Meets Innovation

Pharmaceutical packaging is undergoing a green revolution. Innovations in sustainable packaging materials, such as biodegradable plastics and recyclable paperboard, align with both environmental concerns and consumer preferences. Eco-friendly packaging not only reduces your carbon footprint but also enhances your brand’s image as a responsible corporate citizen.

Smart Packaging for Enhanced Engagement

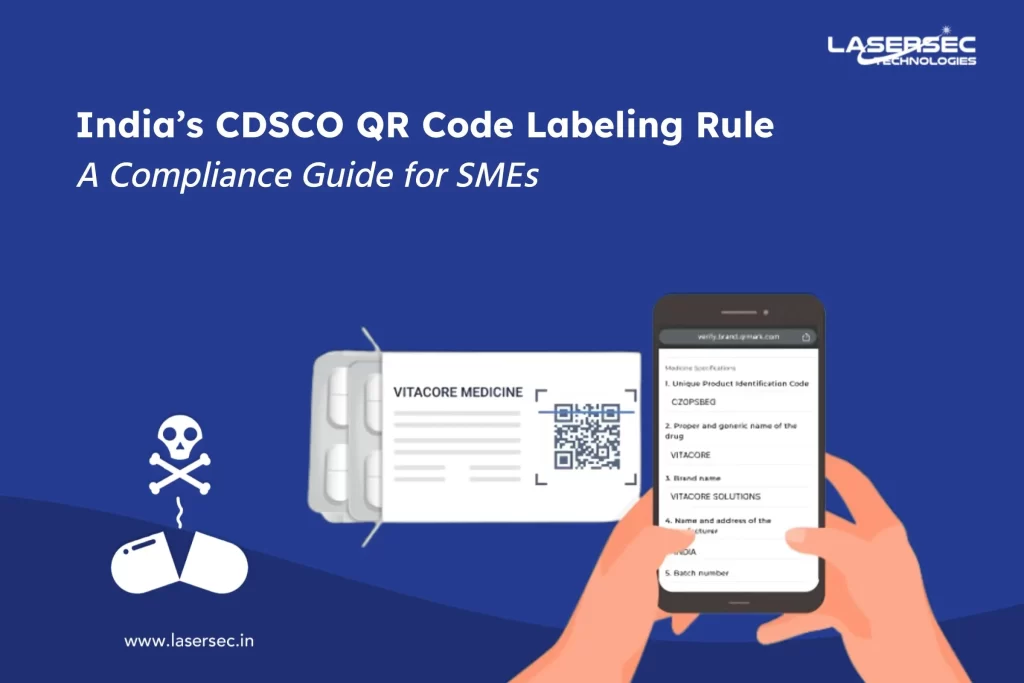

The integration of smart packaging technologies is revolutionizing the industry. QR codes, NFC chips, and RFID tags enable pharmaceutical companies to engage directly with consumers through their smartphones. This not only provides valuable product information but also opens doors for brand loyalty programs and post-purchase interactions.

Tamper-Proof and Authentication Features

Security remains a paramount concern in pharmaceutical packaging design. Tamper-evident seals, holograms, and unique serialization codes act as robust deterrents against counterfeit products. Consumers and supply chain stakeholders can easily verify the authenticity of a product, ensuring their safety and your brand’s integrity.

Child-Resistant and Senior-Friendly Designs

Customizing packaging to meet the needs of specific consumer demographics is another innovative trend. Child-resistant packaging designs protect young ones from accidental ingestion, meeting regulatory requirements. Simultaneously, senior-friendly packaging incorporates features like easy-to-open caps and larger fonts to cater to the aging population.

Customization and Personalization

In the age of personalization, pharmaceutical packaging is no exception. Custom packaging designs that cater to specific patient groups or diseases are gaining popularity. These designs not only enhance the patient experience but also reinforce the brand’s commitment to individualized healthcare solutions.

Regulatory Compliance

Navigating the complex world of pharmaceutical regulations is a must for any packaging innovation. Staying updated with the latest guidelines ensures that your innovative designs not only impress but also adhere to legal standards. Compliance is not just a requirement; it’s the foundation of trust.

Balancing Innovation with Safety

While innovative packaging designs are essential for branding and consumer engagement, they must never compromise safety. A well-designed packaging solution should effectively protect the product from external factors while ensuring ease of use and compliance with regulatory standards.

The journey from an idea to market-ready pharmaceutical packaging is a dynamic process marked by innovation, sustainability, security, and brand identity. Today’s pharmaceutical packaging designs align with consumer expectations for sustainability, engagement, and safety. By embracing the latest trends and technologies, pharmaceutical companies can not only protect their products but also leave a lasting impression on consumers, fostering trust and loyalty.

We, Lasersec Technologies, are leading anti-counterfeit solutions manufacturers that can secure the supply chains, protect the brand reputation, and ensure consumer safety.

If you’re a manufacturer or business and looking for smart packaging for your products, look no further than us. We have the knowledge, experience, and expertise to help you to find the best solution that works for your business.

Reach out to us to discuss and our team will provide you with tailored solutions and support to make the process as smooth as possible. We also One Stop Solution to fight against counterfeit and create a more secure environment for your business. With less counterfeiting, you can maintain sales and increase customer trust.

Stay proactive, stay vigilant, and invest in the right anti-counterfeit solutions to ensure a counterfeit-free future.

About Lasersec Technologies

We are one of the leading holographic solutions manufacturing company, that are used as an anti-counterfeiting device. Our R&D team from the production area is constantly dedicated to finding innovative solutions against counterfeits. Thus, we proudly emphasize on the fact that all our solutions are original ones without any interference from any other outside companies. We have successful business alliances located in Bangladesh, South Africa, Malaysia, Sri Lanka, Nepal, United Kingdom, and countries of Europe.

You can reach us via email at mktg@lasersec.in or by phone at +91-9810213127.