A consumer picks up a face cream, unscrews the lid, and pauses.

Has this been opened before? Has it been refilled, diluted, or contaminated?

In the cosmetics industry, this moment defines trust. Products are applied directly to the skin, lips, and eyes—leaving no margin for doubt. Today, brand reputation alone is no longer enough. Consumers, regulators, and retailers expect visible, verifiable safety at first interaction.

This is why tamper-evident packaging has evolved from an optional feature into a global safety standard for cosmetics brands.

What Is Tamper-Evident Packaging in Cosmetics?

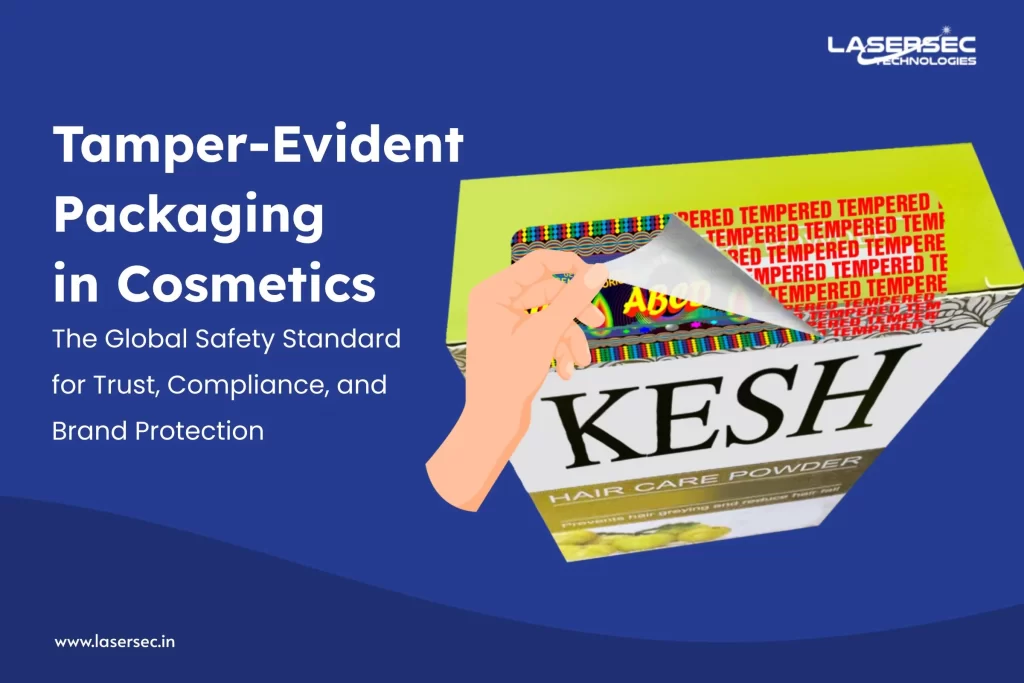

Tamper-evident packaging is a packaging system designed to provide clear, irreversible visual evidence if a cosmetic product has been opened, altered, or compromised after manufacturing.

Once breached, tamper-evident features cannot be restored to their original state—ensuring consumers can immediately identify product integrity before first use.

Why Tamper-Evident Packaging Is Critical in the Cosmetics Industry

Cosmetics are inherently sensitive products. Even minor interference can result in:

- Microbial contamination

- Skin irritation or allergic reactions

- Reduced product efficacy

- Serious consumer safety risks

At the same time, cosmetic brands globally face rising exposure to:

- Product refilling and reuse of original containers

- Unauthorized opening during transit or retail handling

- Counterfeit or diluted formulations entering grey markets

- Increasing regulatory scrutiny on packaging integrity and labeling

Tamper-evident packaging directly addresses these risks by making interference immediately visible.

If a product has been compromised, the packaging itself communicates it—without instructions or explanation.

Common Tamper-Evident Solutions Used in Cosmetic Packaging

- Tamper-Proof Seals : Applied on caps or closures, these seals break or tear irreversibly upon first opening. Once damaged, they cannot be resealed, clearly indicating prior access.

- Void and Destructible Labels : Void & Tamper Proof Labels reveal a permanent message or pattern when removed. Destructive labels fragment on tampering, preventing reuse and eliminating the possibility of concealment.

- Inner Seals and Liners : Placed beneath caps of creams, lotions, and serums, inner seals protect formulations from exposure while offering immediate visual assurance of freshness and safety.

These solutions are intentionally intuitive. Consumers instantly know whether a product is safe—without reading instructions or relying on assumptions.

How Tamper-Evident Packaging Builds Consumer Trust

Trust in cosmetics begins before texture, fragrance, or results. It begins with safety perception.

Tamper-evident features help brands:

- Reassure consumers that the product is untouched

- Reduce hesitation at the point of purchase

- Strengthen confidence during first use

- Reinforce a brand’s commitment to consumer well-being

For both premium and mass-market cosmetics, this visible layer of protection directly influences repeat purchases, reviews, and long-term loyalty.

Is Tamper-Evident Packaging Mandatory for Cosmetics?

While regulations vary by region, global regulatory bodies increasingly expect preventive packaging safety measures, especially for products applied directly to the body.

Tamper-evident packaging supports compliance with:

- US FDA cosmetic safety and labeling expectations

- EU Cosmetic Regulation (EC) No 1223/2009

- ASEAN Cosmetic Directive (ACD)

- Middle East and GCC cosmetic compliance frameworks

For quality assurance and regulatory teams, tamper-evident packaging demonstrates:

- Proactive risk mitigation

- Control over post-manufacturing interference

- Audit readiness and quality accountability

It is no longer only about compliance—it is about responsibility.

Beyond Safety: Protecting Cosmetic Brand Reputation

A single compromised cosmetic product can undo years of brand trust.

Negative reviews, safety complaints, or regulatory actions often spread faster than corrective responses.

Tamper-evident packaging acts as a frontline brand protection mechanism by:

- Reducing the likelihood of altered products reaching consumers

- Limiting reputational damage caused by external supply chain manipulation

- Protecting brands from liability linked to misuse or contamination

In an era of instant social proof and rapid information sharing, prevention is significantly more effective than damage control.

How We Support Cosmetic Brands with Tamper-Evident Solutions

We work closely with cosmetic manufacturers, packaging developers, and compliance teams to integrate tamper-evident packaging solutions that align with product design, regulatory requirements, and consumer expectations.

Our approach focuses on:

- Selecting the right combination of seals, labels, and liners

- Ensuring clear tamper visibility without disrupting aesthetics

- Supporting scalability across global markets and SKUs

Explore our range of tamper-evident holographic labels designed for sensitive consumer products.

By embedding protection directly into the packaging journey, we help cosmetic brands strengthen safety, consistency, and trust—quietly and effectively.

The Future of Cosmetic Packaging Safety

As consumer awareness rises and regulations continue to evolve, tamper-evident packaging will increasingly define responsible cosmetic brands.

It is no longer a secondary feature.

It is a signal of integrity, accountability, and commitment to consumer safety.

For cosmetics—where trust, safety, and experience intersect—tamper-evident packaging sets the standard that consumers now expect and remember.